New Laser Laboratory at Shanghai Jiao Tong University German-Chinese for Cladding and Cooperation

source:laserfair.com

keywords:

Time:2017-04-11

Laserline GmbH, headquartered in Germany, has supported the project SIGLAM with two diode laser systems: One laser with 8 kW laser power and 60 mm mrad (LDF 8000-60); the other system with 3 kW laser power and also 60 mm mrad (LDF 3000-60). The laser systems are highly been suited for additive manufacturing applications but also for cladding applications. With the joint collaboration and the expertise from all project partners, new technologies in cladding and additive manufacturing processes can be explored.

The facility of the laser sources at Shanghai Jiao Tong University builds a perfect location for development and research in these special and innovative applications. Through this collaboration between SJTU (China) and Laserline, the two partners are willing to focus on additive manufacturing and cladding markets such as tool manufacturing, aircraft construction, automotive manufacturing, prototype construction and more industries. Both project partners give their contribution to a well-functioning cooperation.

With additive manufacturing, new production opportunities present themselves, which significantly differ from conventional manufacturing processes. Complex components are built via additive manufacturing. based on the processing principle of cladding, three-dimensional layers can be created by stacking up the individual layers. Complex structures can be generated with a wire or powder with low material usage. A very interesting and promising approach in this area is to integrate the laser source into machine tools. This combination of additive and subtractive tools can achieve a new level of manufacturing.

Cladding is an established process for creating and recovering coatings that are supposed to protect metal components from wear and tear. Refined components are used during cladding in a wide range of applications – from heavy industry to vehicle production and even agriculture. The main advantages are high flexibility and short processing periods, low warpage of processed component parts, and fine-grained coatings with excellent adhesion.

Having established a very well-working relationship between Germany and China, clearly this new partnership will be a step for the next level in the sino-laser collaboration.

All parties would like to thank the support from BMBF (German Federal Ministry of Education and Research) and MOST (Chinese Ministry of Science and Technology).

about Laserline

Being the world-wide leading manufacturer of diode lasers for material processing, Laserline and their products have become the embodiment of this innovative technology. More than 4,000 high power diode lasers from Laserline are used in production processes all over the world, and have proven their efficiency in a wide range of different applications.

Laserline started their business in 1997 as one of the pioneers in the area of diode lasers for industrial material processing. The building complex on the premises of the company in Mülheim-Kärlich, Germany offers space for future growth. The company has about 270 employees as well as several international subsidiaries and representatives in key markets and areas that provide first class worldwide customer service.

Contact details:

Laserline GmbH

Markus Rütering

Fraunhofer Straße

56218 Mülheim-Kärlich

Germany

Tel. +49 2630 964 0

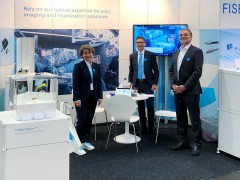

Picture 1: Ceremony for unveiling the joint lab plaque (from left: Prof. Wu Yixiong, member of board of directors, Vice President of CWS – all at JiaoTong University, Prof. Harald Kohn, Co-ordinator Sino-German projects, Markus Ruetering, Sales Manager Asia for Laserline)

Picture 2: Celebrating the new Partnership (from left: Associate Prof. Huang Jian, Vice director of Laserprocessing Lab at JiaoTong University , Prof. Li Zhuguo, Director of Laserprocessing Lab at JiaoTong University, Markus Ruetering, Sales Manager Asia for Laserline, Prof. Harald Kohn, Co-ordinator Sino-German projects)

- RoboSense is to Produce the First Chinese Multi-beam LiDAR

- China is to Accelerate the Development of Laser Hardening Application

- Han’s Laser Buys Canadian Fiber Specialist CorActive

- SPI Lasers continues it expansion in China, appointing a dedicated Sales Director

- Laser Coating Removal Robot for Aircraft

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays

New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays A new industrial compression module by Amplitude

A new industrial compression module by Amplitude Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of

Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>

Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>