Concept Laser reports an increase in sales of 88% for the first half of 2016

source:Concept Laser

Time:2016-08-25

Attractive range of products and strong innovative performance boost the company’s figures

Concept Laser is yet again able to post record figures for the 1st half of 2016. As the management of the company emphasizes, the transition to industrial series production has really taken hold in a number of sectors. The aerospace industry in particular as well as medical technology but other sectors too are increasingly committed to 3D metal printing. This again presents Concept Laser with a high level of dynamism which is being attended to with numerous structural and organizational measures. Sales continue to perform very well. In the 1st half of 2016, the increase in sales compared to the same period in the previous year (1st half of 2015) was an impressive 88%.

The increase in sales therefore exceeded the target figures. Frank Herzog, President & CEO of Concept Laser, says: “The transition to the industrial series production of additively manufactured metal parts is increasingly stimulating our growth. But this is where our constant aspiration to advance the technology with further innovations and cater for the needs of the market and our customers in the best way possible is also paying off. From the end of 2016, the next logical step will then be the commercial launch of our new machine architecture.” This growth is also supported by service providers that are upgrading their fleet of machinery and installations so that they are able to cater for the great demand for additively manufactured parts made from metal. In addition, the multilaser technology and the X line 2000R, which has the world’s largest build envelope for powder-bed-based laser melting with metals, are making their contribution to the success. The growth path has also been reflected in the number of employees, which has risen to 190 (as of June 30, 2016). As things stand today, Concept Laser also expects sales to exceed their target for the second half of 2016.

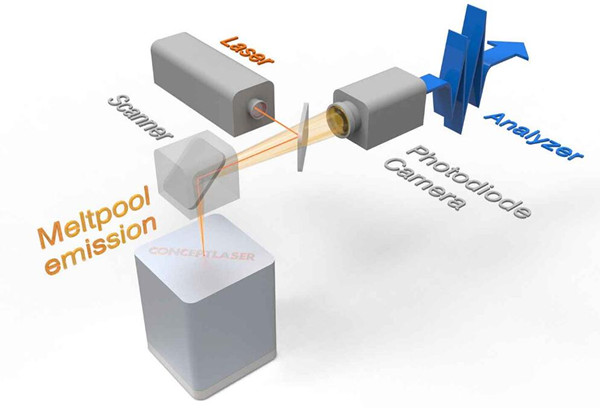

In-situ process monitoring with QM Meltpool 3D: Pioneering role when it comes to quality assurance and monitoring

In-situ process monitoring has been one of the key strategic fields of technology for Concept Laser since as early as 2004, long before the market was demanding such a solution. This far-sighted approach resulted in the development and market launch of QM Meltpool 3D, the first process monitoring tool of its type which received the “International Additive Manufacturing Award 2016” (IAMA) at metav 2016. QM Meltpool 3D provides quality-relevant data for process monitoring and documentation in real time, and this is absolutely essential for part manufacturing and qualification in particular for the aerospace and medical technology sectors. The system records positional characteristics of the meltpool while the part is being created. This data can be visualized on a three-dimensional map and analyzed by the user. According to the manufacturer, this analytical tool is comparable to the HD resolution of computed tomography (CT). The tool also saves time and money compared to conventional part testing. But the practical added value provided by this innovation is not just an original tool for active quality assurance. In manufacturing, build jobs can be optimized through iterative variation of the parameters. Support structures can be adapted and in particular the upstream part structure can be designed to be easier to fabricate. Not least new opportunities are emerging in material research.

New machine architecture as the next milestone

The next milestone will be, from the end of 2016, the commercial availability of the new machine architecture based on the vision of the “AM Factory of Tomorrow”. In future, there will be stand-alone process stations for the build process with a build envelope of 400 x 400 x >400 mm³ which will have 1 to 4 laser systems featuring multilaser technology with 400W to 1,000W laser sources. There is also a new 2-axis coating process allowing the return run of the coater to be performed alongside the exposure. This results in a considerable time saving during the coating process. An automated tool changing system, as is the case with CNC machine technology, also promises a high level of flexibility, time advantages when setting up the machine, and reduces the level of manual intervention by the operator.

For set-up and disarming processes, there are physically separate, autonomous handling stations. This enables “optimum use windows” right through to the ideal of 24/7 availability of the machine technology. An automated material flow is another unique selling point. This allows self-contained modules for transport and material provision to be used on the process stations. This and the decoupling of the process and handling stations simplify each production assignment. In parallel rather than sequentially: This basic idea behind the new machine architecture from Concept Laser results in an increase in availability and downtimes kept to a minimum. But the basic concept of the “AM Factory of Tomorrow” does in fact go beyond this approach and also envisages linking up with traditional manufacturing methods, e.g. in the post-processing of the parts. The realization of the key idea of “Industrie 4.0” and the machine solution which users have asked for to allow the economical series production of metallic parts are being consistently implemented.

MOST READ

- RoboSense is to Produce the First Chinese Multi-beam LiDAR

- China is to Accelerate the Development of Laser Hardening Application

- Han’s Laser Buys Canadian Fiber Specialist CorActive

- SPI Lasers continues it expansion in China, appointing a dedicated Sales Director

- Laser Coating Removal Robot for Aircraft

PRODUCTS

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays

New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays A new industrial compression module by Amplitude

A new industrial compression module by Amplitude Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of

Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>

Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>